Digital peristaltic pumps are commonly used in a variety of applications that require accurate and controlled fluid dosing or transfer.

Here are some typical applications where digital peristaltic pumps are utilized:

- Laboratory and Research: Digital peristaltic pumps are extensively used in laboratory settings for precise dispensing of fluids in scientific experiments, analytical instrumentation, and sample preparation. They enable accurate addition of reagents, buffers, standards, or samples, ensuring reproducibility and precision in research and analysis.

- Medical and Pharmaceutical: Digital peristaltic pumps find application in medical and pharmaceutical fields for dosing medications, infusions, or intravenous fluids. The pumps can be programmed to deliver precise volumes at specific rates, allowing for controlled drug administration or patient treatment.

- Biotechnology and Bioprocessing: Digital peristaltic pumps are utilized in biotechnology and bioprocessing applications, including cell culture, fermentation, or media preparation. They provide accurate and gentle transfer of sensitive fluids such as cell suspensions, culture media, or additives, minimizing the risk of cell damage or contamination.

- Food and Beverage Industry: Digital peristaltic pumps are employed in the food and beverage industry for dosing additives, flavorings, colorings, or ingredients during production processes. These pumps ensure precise and controlled addition of liquids, maintaining consistency in product quality and taste.

- Water and Wastewater Treatment: Digital peristaltic pumps are used in water and wastewater treatment facilities for chemical dosing. They provide accurate and controlled delivery of chemicals, such as disinfectants, coagulants, pH adjusters, or flocculants, improving treatment efficiency and maintaining water quality standards.

- Environmental Monitoring: Digital peristaltic pumps are utilized in environmental monitoring applications, such as air sampling or water sampling. They allow for precise dosing of sampling reagents, ensuring accurate analysis and detection of pollutants, contaminants, or specific parameters in environmental samples.

- Industrial Processes: Digital peristaltic pumps find use in various industrial processes that require controlled dosing or transfer of fluids. They are employed in industries such as chemical manufacturing, pharmaceutical production, cosmetics, or oil and gas, where accurate and repeatable fluid handling is crucial.

- Agriculture and Horticulture: Digital peristaltic pumps are utilized in agriculture and horticulture for precise dosing of fertilizers, pesticides, or nutrient solutions. They ensure accurate delivery of the required concentrations, promoting optimal plant growth and yield.

- Printing and Packaging: Digital peristaltic pumps are used in printing and packaging industries for precise ink dosing or adhesive application. They enable controlled and consistent delivery of fluids, ensuring accurate printing or bonding processes.

Digital peristaltic pumps offer benefits such as accurate dosing, digital peristaltic pump gentle fluid handling, programmability, and easy integration with automation systems. Their versatility and reliability make them valuable tools in various industries that require precise and controlled fluid transfer or dosing.

Here’s some additional information about digital peristaltic pumps:

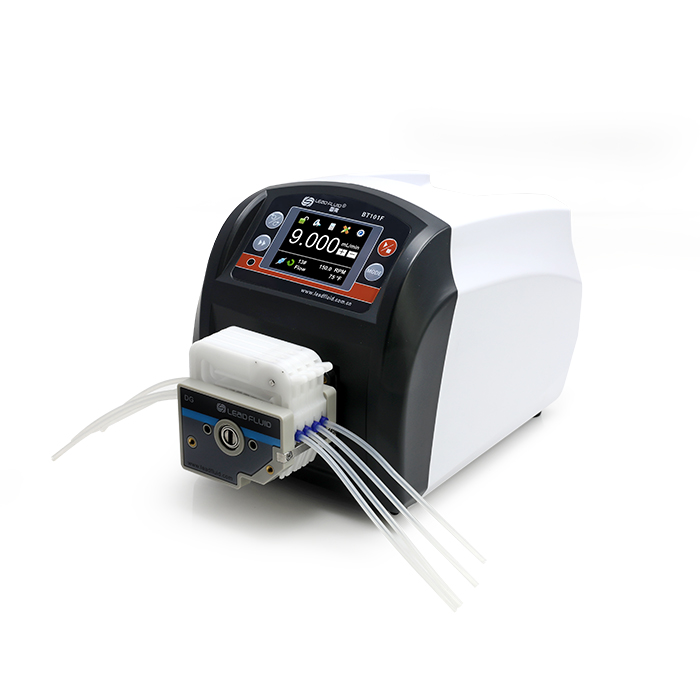

- Programmability and Control: Digital peristaltic pumps are equipped with electronic interfaces and control systems that allow for precise programming and control of dosing parameters. Users can set parameters such as flow rates, dosing volumes, dosing intervals, and even complex dosing profiles. This programmability enables automation, repeatability, and customization of dosing processes.

- Multiple Channels: Digital peristaltic pumps often have multiple pump channels or heads, which allow for simultaneous dosing of different fluids or the creation of complex dosing combinations. This feature is particularly useful in applications where multiple reagents or fluids need to be dosed in specific ratios or sequences.

- Dispensing Modes: In addition to continuous dosing, digital peristaltic pumps offer different dispensing modes to meet various application requirements. These modes may include timed dispensing, volume-based dispensing, or dose-on-demand dispensing. Timed dispensing allows for dosing at predefined time intervals, volume-based dispensing allows for dosing specific volumes, and dose-on-demand dispensing enables dosing triggered by external signals or sensors.

- Calibration and Accuracy: Digital peristaltic pumps can be calibrated to ensure accurate dosing by accounting for factors such as tubing variations, pump head characteristics, or fluid properties. Calibration procedures involve measuring the actual dosed volumes and adjusting the pump settings accordingly, resulting in improved accuracy and precision.

- Flow Monitoring and Feedback: Advanced digital peristaltic pumps may feature flow monitoring and feedback mechanisms. These features enable real-time monitoring of the dosed fluid flow rate, allowing for adjustments to maintain the desired dosing parameters even in the presence of external factors that may affect flow rates. Flow feedback ensures accurate and consistent dosing performance.

- Tubing Selection and Compatibility: Digital peristaltic pumps require appropriate tubing for fluid transfer. Various tubing materials, sizes, and formulations are available to suit different fluid types, viscosities, and chemical compatibilities. The pump heads are designed to accommodate different tubing sizes, making it easy to adapt to specific application requirements.

- Ease of Maintenance: Digital peristaltic pumps are designed for easy maintenance and tubing replacement. Pump heads are typically designed to allow quick and simple tubing changes, minimizing downtime and ensuring efficient operation. Regular tubing replacement or cleaning helps maintain optimal performance and prevent cross-contamination.

- Data Logging and Connectivity: Some digital peristaltic pumps offer data logging capabilities, allowing for the recording and analysis of dosing parameters, dosing history, or alarms. They may also have connectivity options such as USB ports or wireless interfaces, enabling data transfer, remote control, or integration with external systems or software platforms.

- Portability and Benchtop Models: Digital peristaltic pumps are available in various sizes and configurations, including portable handheld models and larger benchtop units. Portable models offer flexibility for field applications or situations where mobility is required, while benchtop models provide higher flow rates and multiple channels for more demanding dosing tasks.

Digital peristaltic pumps are widely used in industries and applications that require precise and controlled dosing of fluids. Their programmability, multiple channels, accuracy, and ease of maintenance make them versatile tools for various dosing needs. Whether in research laboratories, medical settings, industrial processes, or environmental monitoring, digital peristaltic pumps play a vital role in achieving accurate and efficient fluid delivery.